2023 FORD E-350 Wheels and Tires User Guide

The wheels and tires on the 2023 Ford E-350 are a perfect combination of style and function, made to last and work well. Ford’s dedication to quality and safety is shown by the E-350’s wheels and tires, which are made to handle a variety of terrains and provide a smooth ride. Advanced features like the Tire Pressure Monitoring System (TPMS) and the ability to change tires for different seasons give owners the confidence to drive on a variety of road conditions. This shows that the vehicle is ready for both work and play.

2023 FORD F-SERIES SUPER DUTY Specs, Price, Features and Mileage

Wheels and Tires

GENERAL INFORMATION

Notice to Utility Vehicle, Van and Truck Owners

WARNING: Utility vehicles have a significantly higher rollover rate than other types of vehicles. To reduce the risk of serious injury or death from a rollover or other crash you must avoid sharp turns and abrupt maneuvers, drive at safe speeds for the conditions, keep tires properly inflated, never overload or improperly load your vehicle, and make sure every passenger is properly restrained.

WARNING: In a rollover crash, an unbelted person is significantly more likely to die than a person wearing a seat belt. All occupants must wear seat belts. Children and infants must use appropriate restraints to minimize the risk of injury or ejection.

Utility vehicles and trucks handle differently than passenger cars in the various driving conditions that are encountered on streets, highways and off-road. Utility vehicles and trucks are not designed for cornering at speeds as high as passenger cars any more than low-slung sports cars are designed to perform satisfactorily under off-road conditions.

How Your Vehicle Differs from Other Vehicles

Sport-utility vehicles, vans and trucks can differ from some other vehicles in a few noticeable ways. Your vehicle may be:

- Higher – to allow higher load-carrying capacity and to allow it to travel over rough terrain without getting hung up or damaging underbody components.

- Shorter – to give it the capability to approach inclines and drive over the crest of a hill without getting hung up or damaging underbody components. All other things held equal, a shorter wheelbase may make your vehicle quicker to respond to steering inputs than a vehicle with a longer wheelbase.

- Narrower – to provide greater maneuverability in tight spaces, particularly in off-road use.

E166373

As a result of the above dimensional differences, sport-utility vehicles, vans and trucks often will have a higher center of gravity and a greater difference in center of gravity between the loaded and unloaded condition.

These differences that make your vehicle so versatile also make it handle differently than an ordinary passenger car.

TIRE CARE

Information About Uniform Tire Quality Grading

Tire Quality Grades apply to new pneumatic passenger car tires.

The Quality grades can be found where applicable on the tire sidewall between tread shoulder and maximum section width. For example: Treadwear 200

Traction AA Temperature A.

These Tire Quality Grades are determined by standards that the United States Department of Transportation has set.

Tire Quality Grades apply to new pneumatic passenger car tires.

They do not apply to deep tread, winter-type snow tires, space-saver or temporary use spare tires, light truck or LT type tires, tires with nominal rim diameters of 10 to 12 inches or

limited production tires as defined in Title 49 Code of Federal

Regulations Part 575.104 (c)(2).

U.S. Department of Transportation Tire quality

grades: The U.S. Department of Transportation requires Ford Motor Company to give you the following information about tire grades exactly as the government has written it.

Treadwear

The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified government test course. For example, a tire graded 150 would wear one and one-half (1 ½) times as well on the government course as a tire graded 100. The relative performance of tires depends upon the actual conditions of their use, however, and may depart significantly from the norm due to variations in driving habits, service practices, and differences in road characteristics and climate.

Traction AA A B C

WARNING: The traction grade assigned to this tire is based on straight-ahead braking traction tests and does not include acceleration, cornering, hydroplaning or peak traction characteristics.

The traction grades, from highest to lowest are AA, A, B, and C. The grades represent the tire’s ability to stop on wet pavement as measured under controlled conditions on specified government test surfaces of asphalt and concrete. A tire marked C may have poor traction performance.

Temperature A B C

WARNING: The temperature grade for this tire is established for a tire that is properly inflated and not overloaded. Excessive speed, underinflation, or excessive loading, either separately or in combination, can cause heat buildup and possible tire failure.

The temperature grades are A

(the highest), B and C, represent the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel. Sustained high temperature can cause the material of the tire to degenerate and reduce tire life, and excessive temperature can lead to sudden tire failure. Grade C corresponds to a level of performance that all passenger car tires must meet under the Federal Motor Vehicle Safety Standard No. 139. Grades B and A represent higher levels of performance on the laboratory test wheel than the minimum required by law.

Glossary of Tire Terminology

* Tire label: A label showing the original equipment tire sizes, recommended inflation pressure and the maximum weight the vehicle can carry.

* Tire Identification Number (TIN): A number on the sidewall of each tire providing information about the tire brand and manufacturing plant, tire size and date of manufacture. Also referred to as DOT code.

* Inflation pressure: A measure of the amount of air in a tire.

* Standard load: A class of P-metric or Metric tires designed to carry a maximum load at set pressure. For example: For

P-metric tires 35 psi (2.4 bar) and for Metric tires 36 psi (2.5 bar). Increasing the inflation pressure beyond this pressure does not increase the tire’s load carrying capability.

*Extra load: A class of P-metric or Metric tires designed to carry a heavier maximum load at 42 psi (2.9 bar). Increasing the inflation pressure beyond this pressure does not increase the tire’s load-carrying capability.

* kPa: Kilopascal, a metric unit of air pressure.

* PSI: Pounds per square inch, a standard unit of air pressure.

* Cold tire pressure: The tire pressure when the vehicle has been stationary and out of direct sunlight for an hour or more and prior to the vehicle being driven for 1.0 mi (1.6 km).

* Recommended inflation pressure: The cold inflation pressure found on the Safety Compliance Certification Label (affixed to either the door hinge pillar, door-latch post, or the door edge that meets the door-latch post, next to the driver’s seating position), or Tire Label located on the B-pillar or the edge of the driver’s door.

B-pillar: The structural member at the side of the vehicle behind the front door.

* Bead area of the tire: Area of the tire next to the rim.

* Sidewall of the tire: Area between the bead area and the tread.

* Tread area of the tire: Area of the perimeter of the tire that contacts the road when mounted on the vehicle.

* Rim: The metal support (wheel) for a tire or a tire and tube assembly upon which the tire beads are seated.

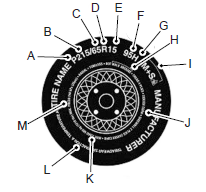

Information contained on the Tire Sidewall

Both United States and Canada Federal regulations require tire manufacturers to place standardized information on the sidewall of all tires. This information identifies and describes the fundamental characteristics of the tire and also provides a U.S. DOT Tire Identification Number for safety standard certification and in case of a recall.

Information on P-Type Tires

P215/65R15 95H is an example of a tire size, load index and speed rating. The definitions of these items are listed below. (Note that the tire size, load index and speed rating for your vehicle may be different from this example.)

A. P: Indicates a tire, designated by the Tire and Rim Association, that may be used for service on cars, sport utility vehicles, minivans and light trucks.

Note: If your tire size does not begin with a letter this may mean it is designated by either the European Tire and Rim Technical Organization or the Japan Tire Manufacturing Association.

B. 215: Indicates the nominal width of the tire in millimeters from sidewall edge to sidewall edge. In general, the larger the number, the wider the tire.

C. 65: Indicates the aspect ratio which gives the tire’s ratio of height to width.

D. R: Indicates a radial type tire.

E. 15: Indicates the wheel or rim diameter in inches. If you change your wheel size, you have to purchase new tires to match the new wheel diameter.

F. 95: Indicates the tire’s load index. It is an index that relates to how much weight a tire can carry. You may find this information in your owner’s manual. If not, contact a local tire dealer.

Note: You may not find this information on all tires because it is not required by federal law.

G. H: Indicates the tire’s speed rating. The speed rating denotes the speed at which a tire is designed to be driven for extended periods of time under a standard condition of load and inflation pressure. The tires on your vehicle may operate at different conditions for load and inflation pressure. These speed ratings may need to be adjusted for the difference in conditions. The ratings range from 81–186 mph (130–299 km/h). These ratings are listed in the following chart.

Note: You may not find this information on all tires because it is not required by federal law.

| Letter rating | mph ( km/h) |

| L | 75 (120) |

| M | 81 (130) |

| N | 87 (140) |

| Q | 99 (159) |

| R | 106 (171) |

| S | 112 (180) |

| T | 118 (190) |

| U | 124 (200) |

| H | 130 (210) |

| V | 149 (240) |

| Letter rating | mph ( km/h) |

| W | 168 (270) |

| Y | 186 (299) |

Note: For tires with a maximum speed capability over 149 mph

(240 km/h), tire manufacturers sometimes use the letters ZR. For those with a maximum speed capability over 186 mph (299 km/h), tire manufacturers always use the letters ZR.

H. U.S. DOT Tire Identification Number: This begins with the letters DOT and indicates that the tire meets all federal standards. The next two numbers or letters are the plant code designating where it was manufactured, the next two are the tire size code and the last four numbers represent the week and year the tire was built. For example, the numbers 317 mean the 31st week of 1997. After 2000 the numbers go to four digits. For example, 2501 means the 25th week of 2001. The numbers in between are identification codes used for traceability. This information is used to contact customers if a tire defect requires a recall.

I. M+S or M/S: Mud and Snow, or

AT: All Terrain, or

AS: All Season.

J. Tire Ply Composition and Material Used: Indicates the number of plies or the number of layers of rubber-coated fabric in the tire tread and sidewall. Tire manufacturers also must indicate the ply materials in the tire and the sidewall, which include steel, nylon, polyester, and others.

K. Maximum Load: Indicates the maximum load in kilograms and pounds that can be carried by the tire. (affixed to either the door hinge pillar, door-latch post, or the door edge that meets the door-latch post, next to the driver’s seating position), or Tire Label located on the B-pillar or the edge of the driver’s door.

L. Treadwear, Traction and Temperature Grades:

*Treadwear: The treadwear grade is a comparative rating based on the wear rate of the tire when tested under controlled conditions on a specified government test course. For example, a tire graded 150 would wear 1½ times as well on the government course as a tire graded 100.

* Traction: The traction grades, from highest to lowest are AA, A, B, and C. The grades represent the tire’s ability to stop on wet pavement as measured under controlled conditions on specified government test surfaces of asphalt and concrete. A tire marked C may have poor traction performance.

* Temperature: The temperature grades are A (the highest), B, and C, representing the tire’s resistance to the generation of heat and its ability to dissipate heat when tested under controlled conditions on a specified indoor laboratory test wheel.

M. Maximum Inflation

Pressure: Indicates the tire manufacturer’s maximum permissible pressure or the pressure at which the maximum load can be carried by the tire. This pressure is normally higher than the vehicle manufacturer’s recommended cold inflation pressure which can be found on the Safety Compliance Certification Label (affixed to either the door hinge pillar, door-latch post, or the door edge that meets the door-latch post, next to the driver’s seating position), or Tire Label located on the B-pillar or the edge of the driver’s door. The cold inflation pressure should never be set lower than the recommended pressure on the vehicle label.

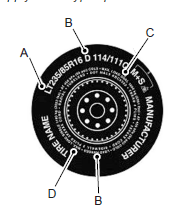

The tire suppliers may have additional markings, notes or warnings such as standard load or radial tubeless. Additional Information Contained on the Tire Sidewall for LT Type Tires

Note: Tire Quality Grades do not apply to this type of tire.

LT-type tires have some additional information beyond those of P type tires. These differences are described below .A. LT: Indicates a tire, designated by the Tire and Rim Association, that is intended for service on light trucks.

B. Load Range and Load Inflation Limits: Indicates the tire’s load-carrying capabilities and its inflation limits.

C. Maximum Load Dual lb (kg) at psi (kPa) cold: Indicates the maximum load and tire pressure when the tire is used as a dual; defined as four tires on the rear axle (a total of six or more tires on the vehicle).

D. Maximum Load Single lb

(kg) at psi (kPa) cold: Indicates the maximum load and tire pressure when the tire is used as a single; defined as two tires

(total) on the rear axle.

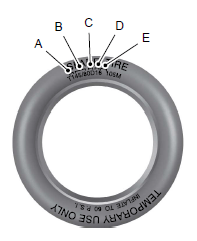

Information on T Type Tires

T145/80D16 is an example of a tire size.

Note: The temporary tire size for your vehicle may be different from this example. Tire Quality Grades do not apply to this type of tire

T type tires have some additional information beyond those of P-type tires. These differences are described below:

A. T: Indicates a type of tire, designated by the Tire and Rim Association, that is intended for temporary service on cars, sport utility vehicles, minivans and light trucks.

B. 145: Indicates the nominal width of the tire in millimeters from sidewall edge to sidewall edge. In general, the larger the number, the wider the tire.

C. 80: Indicates the aspect ratio which gives the tire’s ratio of height to width. Numbers of 70 or lower indicate a short sidewall.

D. D: Indicates a diagonal-type tire. R: Indicates a radial-type tire.

E. 16: Indicates the wheel or rim diameter in inches. If you change your wheel size, you have to purchase new tires to match the new wheel diameter.

Location of the Tire Label

You can find a Tire Label containing tire inflation pressure by tire size and other important information located on the B-Pillar or the edge of the driver’s door.

Inflating Your Tires

Safe operation of your vehicle requires that your tires are properly inflated. Remember that a tire can lose up to half of its air pressure without appearing flat.

Every day before you drive, check your tires. If one looks lower than the others, use a tire gauge to check pressure of all tires and adjust if required.

At least once a month and before long trips, inspect each tire and check the tire pressure with a tire gauge (including spare, if equipped). Inflate all tires to the inflation pressure recommended by Ford Motor Company.

You are strongly urged to buy a reliable tire pressure gauge, as automatic service station gauges may be inaccurate. Ford recommends the use of a digital or dial-type tire pressure gauge rather than a stick-type tire pressure gauge. Use the recommended cold inflation pressure for optimum tire performance and wear. Under-inflation or over-inflation may cause uneven treadwear patterns.

WARNING: Under-inflation is the most common cause of tire failures and may result in severe tire cracking, tread separation or blowout, with unexpected loss of vehicle control and increased risk of injury. Under-inflation increases sidewall flexing and rolling resistance, resulting in heat buildup and internal damage to the tire. It also may result in unnecessary tire stress, irregular wear, loss of vehicle control and accidents. A tire can lose up to half of its air pressure and not appear to be flat!

Always inflate your tires to the Ford recommended inflation pressure even if it is less than the maximum inflation pressure information found on the tire. The Ford recommended tire inflation pressure is found on the Safety Compliance Certification Label or Tire Label (affixed to either the door hinge pillar, door-latch post, or the door edge that meets the door-latch post, next to the driver’s seating position), or Tire Label located on the B-pillar or the edge of the driver’s door. Failure to follow the tire pressure recommendations can cause uneven treadwear patterns and adversely affect the way your vehicle handles

Note: Do not reduce tire pressure to change the ride characteristics of the vehicle. If you do not maintain the inflation pressure at the levels specified by Ford, your vehicle may experience a condition known as shimmy. Shimmy is a severe vibration and oscillation in the steering wheel after the vehicle travels over a bump or dip in the road that does not dampen out by itself. Shimmy may result from significant under-inflation of the tires, improper tires (load range, size, or type), or vehicle modifications such as lift kits. In the event that your vehicle experiences shimmy, you should slowly reduce speed by either lifting off the accelerator pedal or lightly applying the brakes. The shimmy ceases as the vehicle speed decreases.

Maximum Inflation Pressure is the tire manufacturer’s maximum permissible pressure and the pressure at which the maximum load can be carried by the tire. This pressure is normally higher than the manufacturer’s recommended cold inflation pressure which can be found on the Safety Compliance Certification Label (affixed to either the door hinge pillar, door-latch post, or the door edge that meets the door-latch post, next to the driver’s seating position), or Tire Label located on the B-pillar or the edge of the driver’s door. The cold inflation pressure should never be set lower than the recommended pressure on the Safety Compliance Certification Label or Tire Label.

When weather temperature changes occur, tire inflation pressures also change. A 10°F (6°C) temperature drop can cause a corresponding drop of 1 psi (7 kPa) in inflation pressure. Check your tire pressures frequently and adjust them to the proper pressure which can be found on the Safety Compliance Certification Label or Tire Label.

To check the pressure in your tire(s):

- Make sure the tires are cool, meaning they are not hot from driving even a mile.

Note: If you are checking tire pressure when the tire is hot, (for example, driven more than 1.0 mi (1.6 km)), never bleed or reduce air pressure. The tires are hot from driving and it is normal for pressures to increase above recommended cold pressures. A hot tire at or below recommended cold inflation pressure could be significantly under-inflated.

Note: If you have to drive a distance to get air for your tire(s), check and record the tire pressure first and add the appropriate air pressure when you get to the pump. It is normal for tires to heat up and the air pressure inside to go up as you drive. - Remove the cap from the valve on one tire, then firmly press the tire gauge onto the valve and measure the pressure.

- Add enough air to reach the recommended air pressure.

Note: If you overfill the tire, release air by pressing on the metal stem in the center of the valve. Then recheck the pressure with your tire gauge. - Replace the valve cap.

- Repeat this procedure for each tire, including the spare.

Note: Some spare tires operate at a higher inflation pressure than the other tires. For T-type mini-spare tires, (see the Dissimilar spare wheel and tire assembly information for a description. Store and maintain at 60 psi (4.15 bar). For full-size and dissimilar spare tires, see the Dissimilar spare wheel and tire assembly information for a description. Store and maintain at the higher of the front and rear inflation pressure as shown on the Safety Compliance Certification Label or Tire Label. - Visually inspect the tires to make sure there are no nails or other objects embedded that could poke a hole in the tire and cause an air leak.

- Check the sidewalls to make sure there are no gouges, cuts or bulges.

Tire Inflation Information

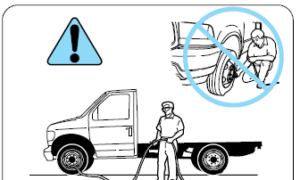

WARNING:

An inflated tire and rim can be very dangerous if improperly used, serviced or maintained. To reduce the risk of serious injury, never attempt to re-inflate a tire which has been run flat or seriously under-inflated without first removing the tire from the wheel assembly for inspection. Do not attempt to add air to tires or replace tires or wheels without first taking precautions to protect persons and property.

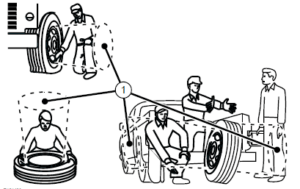

All tires with Steel Carcass Plies (if equipped):

This type of tire utilizes steel cords in the sidewalls. As such, they cannot be treated like normal light truck tires. Tire service, including adjusting tire pressure, must be performed by personnel trained, supervised and equipped according to Federal Occupational Safety and Health Administration regulations. For example, during any procedure involving tire inflation, the technician or individual must utilize a remote inflation device, and ensure that all persons are clear of the trajectory area.

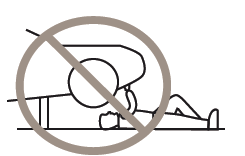

E161438

Note: Stay out of the trajectory (1) as indicated in the illustration.

Inspecting Your Tires and Wheel Valve Stems

Periodically inspect the tire treads for uneven or excessive wear and remove objects such as stones, nails or glass that may be wedged in the tread grooves. Check the tire and valve stems for holes, cracks, or cuts that may permit air leakage and repair or replace the tire and replace the valve stem. Inspect the tire sidewalls for cracking, cuts, bruises and other signs of damage or excessive wear. If internal damage to the tire is suspected, have the tire demounted and inspected in case it needs to be repaired or replaced. For your safety, tires that are damaged or show signs of excessive wear should not be used because they are more likely to blow out or fail.

Improper or inadequate vehicle maintenance can cause tires to wear abnormally. Inspect all your tires, including the spare, frequently, and replace them if one or more of the following conditions exist:

Tire Wear

When the tread is worn down to one sixteenth of an inch (2 millimeters), tires must be replaced to help prevent your vehicle from skidding and hydroplaning. Built-in treadwear indicators, or wear bars, which look like narrow strips of smooth rubber across the tread appears on the tire when the tread is worn down to one sixteenth of an inch2 millimeters).

When the tire tread wears down to the same height as these wear bars, the tire is worn out and must be replaced.

Damage Periodically inspect the tire treads and sidewalls for damage (such as bulges in the tread or sidewalls, cracks in the tread groove and separation in the tread or sidewall). If damage is observed or suspected have the tire inspected by a tire professional. Tires can be damaged during off-road use, so inspection after off-road use is also recommended.

Age

WARNING:

Tires degrade over time depending on many factors such as weather, storage conditions, and conditions of use (load, speed, inflation pressure) the tires experience throughout their lives.

In general, tires should be replaced after six years regardless of tread wear. However, heat caused by hot climates or frequent high loading conditions can accelerate the aging process and may require tires to be replaced more frequently.

You should replace your spare tire when you replace the road tires or after six years due to aging even if it has not been used.

U.S. DOT Tire Identification Number

Both United States and Canada Federal regulations require tire manufacturers to place standardized information on the sidewall of all tires. This information identifies and describes the fundamental characteristics of the tire and also provides a U.S. DOT Tire Identification Number for safety standard certification and in case of a recall.

This begins with the letters DOT and indicates that the tire meets all federal standards. The next two numbers or letters are the plant code designating where it was manufactured, the next two are the tire size code and the last four numbers represent the week and year the tire was built. For example, the numbers 317 mean the 31st week of 1997. After 2000 the numbers go to four digits. For example, 2501 means the 25th week of 2001. The numbers in between are identification codes used for traceability. This information is used to contact customers if a tire defect requires a recall.

Tire Replacement Requirements

Your vehicle is equipped with tires designed to provide a safe ride and handling capability.

WARNING:

Only use replacement tires and wheels that are the same size, load index, speed rating and type (such as P-metric versus LT-metric or all-season versus all-terrain) as those originally provided by Ford. The recommended tire and wheel size may be found on either the Safety Compliance Certification Label (affixed to either the door hinge pillar, door-latch post, or the door edge that meets the door-latch post, next to the driver’s seating position), or the Tire Label which is located on the B-Pillar or edge of the driver’s door. If this information is not found on these labels, then you should contact your authorized dealer as soon as possible. Use of any tire or wheel not recommended by Ford can affect the safety and performance of your vehicle, which could result in an increased risk of loss of vehicle control, vehicle rollover, personal injury and death.

WARNING: To reduce the risk of serious injury, when mounting replacement tires and wheels, you should not exceed the maximum pressure indicated on the sidewall of the tire to set the beads without the additional precautions listed below. If the beads do not seat at the maximum pressure indicated, re-lubricate and try again.

WARNING: For a mounting pressure of more than 20 psi

(1.38 bar) greater than the maximum pressure, a Ford dealer or other tire service professional should do the mounting.

WARNING: Always inflate steel carcass tires with a remote air fill with the person inflating standing at a minimum of 12 ft (3.66 m) away from the wheel and tire assembly.

WARNING: When inflating the tire for mounting pressures up to 20 psi (1.38 bar) greater than the maximum pressure on the tire sidewall, the following precautions must be taken to protect the person mounting the tire:

- Make sure that you have the correct tire and wheel size.

- Lubricate the tire bead and wheel bead seat area again.

- Stand at a minimum of 12 ft (3.6 m) away from the wheel and tire assembly.

- Use both eye and ear protection.

Important: Remember to replace the wheel valve stems when the road tires are replaced on your vehicle

The two front tires or two rear tires should generally be replaced as a pair.

The tire pressure sensors mounted in the wheels are not designed to be used in aftermarket wheels.

The use of wheels or tires not recommended by Ford Motor Company may affect the operation of your tire pressure monitoring system.

If the tire pressure monitoring system indicator is flashing, the system is malfunctioning. Your replacement tire might be incompatible with your tire pressure monitoring system, or some component of the system may be damaged.

Replacing a Tire That is Greenhouse Gas Certified

The tires installed on this vehicle at the factory as original equipment are certified for Greenhouse Gas and Fuel Efficiency regulations. Replacement tires must be of equal or lower rolling resistance level (TRRL or Crr). Consult with your tire supplier(s) for appropriate replacement tires.

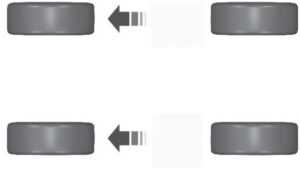

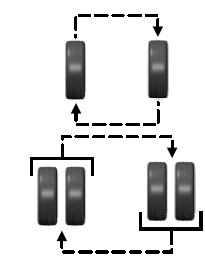

Rear-wheel drive vehicles and four-wheel drive vehicles (front tires at left of diagram).

Dual rear wheel drive vehicle – six tire rotation (front tires at top of diagram).

If your vehicle is equipped with dual rear wheels it is recommended that the front and rear tires (in pairs) be rotated only side to side. We do not recommend splitting up the dual rear wheels. Rotate them side to side as a set. After tire rotation, inflation pressures must be adjusted for the tires new positions in accordance with vehicle requirements.

USING SNOW CHAINS

WARNING: Wheels and tires must be the same size, load index and speed rating as those originally fitted on the vehicle. Use of any other tire or wheel can affect the safety and performance of your vehicle. Additionally, the use of non-recommended tires and wheels can cause steering, suspension, axle, transfer case or power transfer unit failure. Follow the recommended tire inflation pressures found on the Safety Compliance Certification label, or the Tire Label on the B-Pillar or the edge of the driver door. Failure to follow this instruction could result in loss of vehicle control, vehicle rollover, or personal injury or death.

The tires on your vehicle have all-weather treads to provide traction in rain and snow. However, in some climates, you may need to use snow tires and cables. If you need to use cables, it is recommended that steel wheels (of the same size and specifications) be used, as cables may chip aluminum wheels.

Note: The suspension insulation and bumpers help prevent vehicle damage. Do not remove these components from your vehicle when using snow tires and chains.

Follow these guidelines when using snow tires and chains:

- If possible, avoid fully loading your vehicle.

- Install chains securely, verifying that the chains do not touch any wiring, brake lines or fuel lines.

- Drive cautiously. If you hear the chains rub or bang against your vehicle, stop and retighten the chains. If this does not work, remove the chains to prevent damage to your vehicle.

- Remove the snow chains when they are no longer needed. Do not use snow chains on dry roads.

Please contact your upfitter for approved snow chain types/sizes and other recommendations for snow chain use.

TIRE PRESSURE MONITORING SYSTEM (IF EQUIPPED)

WARNING: Changes or modifications not expressively approved by the party responsible for compliance could void the user’s authority to operate the equipment. The term “IC:” before the radio certification number only signifies that Industry Canada technical specifications were met.

WARNING: The tire pressure monitoring system is not a substitute for manually checking tire pressures. You should periodically check tire pressures using a pressure gauge. Failure to correctly maintain tire pressures could increase the risk of tire failure, loss of control, vehicle rollover and personal injury.

Note: Only use tire sealants in roadside emergencies as they may cause damage to the tire pressure monitoring system sensor.

Note: If the tire pressure monitoring system sensor becomes damaged, it may not function.

Each tire, including the spare, if provided, should be checked monthly when cold and inflated to the inflation pressure recommended by the vehicle manufacturer on the vehicle placard or tire inflation pressure label. If your vehicle has tires of a different size than the size indicated on the vehicle placard or tire inflation pressure label, you should determine the proper tire inflation pressure for those tires.

As an added safety feature, your vehicle has been equipped with a Tire Pressure Monitoring System (TPMS) that illuminates a low tire pressure telltale when one or more of your tires is significantly under-inflated. Accordingly, when the low tire pressure telltale illuminates, you should stop and check your tires as soon as possible, and inflate them to the proper pressure. Driving on a significantly under-inflated tire causes the tire to overheat and can lead to tire failure. Under-inflation also reduces fuel efficiency and tire tread life, and may affect the vehicle’s handling and stopping ability.

Please note that the TPMS is not a substitute for proper tire maintenance, and it is the driver’s responsibility to maintain correct tire pressure, even if under-inflation has not reached the level to trigger illumination of the TPMS low tire pressure telltale.

Your vehicle has a TPMS malfunction indicator to indicate when the system is not operating properly. The TPMS malfunction indicator is combined with the low tire pressure telltale. When the system detects a malfunction, the telltale flashes for approximately one minute and then remains continuously illuminated. This sequence continues upon subsequent vehicle start-ups as long as the malfunction exists.

When the malfunction indicator is illuminated, the system may not be able to detect or signal low tire pressure as intended. TPMS malfunctions may occur for a variety of reasons, including the installation of replacement or alternate tires or wheels on the vehicle that prevent the TPMS from functioning properly. Always check the TPMS malfunction telltale after replacing one or more tires or wheels on your vehicle to ensure that the replacement or alternate tires and wheels allow the TPMS to continue to function properly.

This device complies with Part 15 of the FCC Rules and with License exempt RSS Standards of Industry Canada. Operation is subject to the following two conditions:

- This device may not cause harmful interference.

- This device must accept any interference received, including interference that may cause undesired operation.

Changing Tires With a Tire Pressure Monitoring System

Note: Each road tire is equipped with a tire pressure sensor located inside the wheel and tire assembly cavity. The pressure sensor is attached to the valve stem. The pressure sensor is covered by the tire and is not visible unless the tire is removed. Take care when changing the tire to avoid damaging the sensor.

You should always have your tires serviced by an authorized dealer.

Check the tire pressure periodically, at least monthly, using an accurate tire gauge. See Inflating Your Tires in this chapter.

Understanding Your Tire Pressure Monitoring System

The tire pressure monitoring system measures pressure in your four road tires and sends the tire pressure readings to your vehicle. The low tire pressure warning light turns on if the tire pressure is significantly low. Once the light is illuminated, your tires are under-inflated and need to be inflated to the manufacturer’s recommended tire pressure. Even if the light turns on and a short time later turns off, your tire pressure still needs to be checked.

When Your Temporary Spare Tire is Installed

When you replace one of the road tires with the temporary spare, the system continues to identify an issue to remind you that you need to repair and put back on the damaged road wheel and tire assembly on your vehicle.

To restore the full function of the tire pressure monitoring system, have the damaged road wheel and tire assembly repaired and remounted on your vehicle.

When You Believe Your System is Not Operating Properly

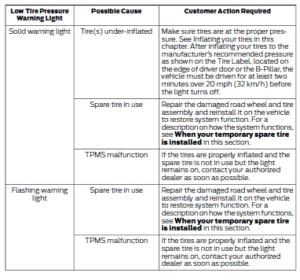

The main function of the tire pressure monitoring system is to warn you when your tires need air. It can also warn you in the event the system is no longer capable of functioning as intended. See the following chart for information concerning your tire pressure monitoring system:

When Inflating Your Tires

When putting air into your tires, such as at a gas station or in your garage, the tire pressure monitoring system may not respond immediately to the air added to your tires.

It may take up to two minutes of driving over 20 mph (32 km/h) for the light to turn off after you have filled your tires to the recommended inflation pressure.

How Temperature Affects Your Tire Pressure

The tire pressure monitoring system monitors tire pressure in each pneumatic tire. When driving in a normal manner, a typical passenger tire inflation pressure may increase about 2–4 psi (14–28 kPa) from a cold start situation. If the vehicle is stationary overnight with the outside temperature significantly lower than the daytime temperature, the tire pressure may decrease about 3 psi (21 kPa) for a drop of 30°F (17°C) in ambient temperature. This lower pressure value may be detected by the tire pressure monitoring system as being significantly lower than the recommended inflation pressure and activate the system warning light for low tire pressure. If the low tire pressure warning light is on, visually check each tire to verify that no tire is flat. If one or more tires are flat, repair as necessary. Check the air pressure in the road tires. If any tire is under-inflated, carefully drive the vehicle to the nearest location where air can be added to the tires. Inflate all the tires to the recommended inflation pressure.

Tire Pressure Monitoring System Reset Procedure

WARNING: To determine the required pressure(s) for your vehicle, see the Safety Compliance Certification Label (on the door hinge pillar,

door-latch post or the door edge that meets the door-latch post, next to the driver seat) or the Tire Label on the B-Pillar or the edge of the driver door.

Note: You need to perform the tire pressure monitoring system reset procedure after each tire rotation.

To provide the vehicle’s load carrying capability, some vehicles require different recommended tire pressures in the front tires as compared to the rear tires. The tire pressure monitoring system on these vehicles illuminate the low tire pressure warning light at two different pressures: one for the front tires and one for the rear tires.

Since tires need to be rotated to provide consistent performance and maximum tire life, the tire pressure monitoring system needs to know when the tires are rotated to determine which set of tires are on the front and which are on the rear. With this information, the system can detect and properly warn of low tire pressures.

System reset tips:

- To reduce the chances of interference from another vehicle, perform the system reset procedure at least 3 ft (1 m) away from another vehicle undergoing the system reset procedure at the same time.

- Do not wait more than two minutes between resetting each tire sensor or the system can time-out and you have to repeat the entire procedure on all four wheels.

- A double horn sounds indicating the need to repeat the procedure.

Performing the System Reset Procedure – Single Rear Wheel

Read the entire procedure before attempting.

- Drive the vehicle above 20 mph (32 km/h) for at least two minutes, then park in a safe location where you can easily get to all four tires and have access to an air pump.

- Place the ignition in the off position and keep the key in the ignition.

- Cycle the ignition to the on position with the engine off.

- Turn the hazard flashers on then off three times. You must accomplish this within 10 seconds. If you successfully enter the reset mode, the horn sounds once, the system indicator flashes and a message shows in the information display. If this does not occur, please try again starting at step 2. If after repeated attempts to enter the reset mode, the horn does not sound, the system indicator does not flash and no message shows in the information display, have the system checked as soon as possible.

- Train the tire pressure monitoring system sensors in the tires using the following system reset sequence starting with the left front tire in the following clockwise order: Left front -driver side front tire, Right front -passenger side front tire, Right rear -passenger side rear tire, Left rear -driver side rear tire.

- Remove the valve cap from the valve stem on the left front tire. Decrease the air pressure until the horn sounds.

Note: The single horn tone confirms that the sensor identification code has been learned by the module for this position. If you hear a double horn, the reset procedure was unsuccessful, and you must repeat it. - Remove the valve cap from the valve stem on the right front tire. Decrease the air pressure until the horn sounds.

- Remove the valve cap from the valve stem on the right rear tire. Decrease the air pressure until the horn sounds.

- Remove the valve cap from the valve stem on the left rear tire. Decrease the air pressure until the horn sounds. Training is complete after the horn sounds for the last tire trained, driver side rear tire, the system indicator stops flashing, and a message shows in the information display.

- Turn the ignition off. If you hear two short tones, the reset procedure was unsuccessful and you must repeat it. If you hear two short beeps when the ignition is off after repeating the procedure, have the system checked as soon as possible

- Set all four tires to the recommended air pressure as indicated on the Safety Compliance Certification Label, affixed to either the door hinge pillar, door-latch post or the door edge that meets the door-latch post, next to the driver seating position or Tire Label located on the B-Pillar or the edge of the driver door.

Performing the System Reset Procedure – Dual Rear Wheel

For further information see

Understanding Your Tire Pressure Monitoring System and refer to Dual Rear Wheel, earlier in this section.

Read the entire procedure before attempting.

- Drive the vehicle above 20 mph (32 km/h) for at least two minutes, then park in a safe location where you can easily get to all six tires and have access to an air pump.

- Place the ignition in the off position and keep the key in the ignition.

- Cycle the ignition to the on position with the engine off.

- Turn the hazard flashers on then off three times. You must accomplish this within 10 seconds. If you successfully enter the reset mode, the horn sounds once, the system indicator flashes and a message shows in the information display. If this does not occur, please try again starting at step 2. If after repeated attempts to enter the reset mode, the horn does not sound, the system indicator does not flash and no message shows in the information display, seek service from your authorized dealer.

- Train the tire pressure monitoring system sensors in the tires using the following system reset sequence starting with the left front tire in the following order: Left front – driver side front tire, Right front – passenger side front tire, Right outer rear -passenger side rear outer tire, Right inner rear -passenger side rear inner tire, Left outer rear – driver side rear outer tire, Left inner rear – driver side rear inner tire.

- Remove the valve cap from the valve stem on the left front tire. Decrease the air pressure until the horn sounds.

Note: The single horn chirp confirms that the sensor identification code has been learned by the module for this position. If a double horn is heard, the reset procedure was unsuccessful, and you must repeat it. - Remove the valve cap from the valve stem on the right front tire. Decrease the air pressure until the horn sounds.

- Remove the valve cap from the valve stem on the right outer rear tire. Decrease the air pressure until the horn sounds.

- Remove the valve cap from the valve stem on the right inner rear tire. Decrease the air pressure until the horn sounds.

- Remove the valve cap from the valve stem on the left outer rear tire. Decrease the air pressure until the horn sounds.

- Remove the valve cap from the valve stem on the left inner rear tire. Decrease the air pressure until the horn sounds. Training is complete after the horn sounds for the last tire trained, the system indicator stops flashing, and a message is shown in the information display.

- Turn the ignition off. If two short horn beeps are heard, the reset procedure was unsuccessful and you must repeat it. If after repeating the procedure and two short beeps are heard when the ignition is turned to off, seek assistance from your authorized dealer.

- Set all six tires to the recommended air pressure as indicated on the Safety Compliance Certification Label, affixed to either the door hinge pillar, door-latch post, or the door edge that meets the door-latch post, next to the driver seating position or Tire Label located on the B-Pillar or the edge of the driver door.

CHANGING A ROAD WHEEL

WARNING: To determine the required pressure(s) for your vehicle, see the Safety Compliance Certification Label (on the door hinge pillar,

door-latch post or the door edge that meets the door-latch post, next to the driver seat) or the Tire Label on the B-Pillar or the edge of the driver door.

Note: You should only use tire sealants in roadside emergencies as they may cause damage to the tire pressure monitoring system sensor.

Note: The tire pressure monitoring system indicator light illuminates when the spare tire is in use. To restore the full function of the monitoring system, all road wheels equipped with tire pressure monitoring sensors must be mounted on the vehicle.

Note: Do not use wheels or lug nuts different than the original equipment, as this may damage the wheel or mounting system.

If you get a flat tire when driving, do not apply the brake heavily. Instead, gradually decrease your speed. Hold the steering wheel firmly and slowly move to a safe place on the side of the road. Have a flat serviced by an authorized dealer to prevent damage to the tire pressure monitoring system sensors. See Tire Pressure Monitoring System (page 209). Replace the spare tire with a road tire as soon as possible. During repairing or replacement of the flat tire, have the authorized dealer inspect the tire pressure monitoring system sensor for damage.

Dissimilar Spare Wheel and Tire Assembly Information

WARNING:

Failure to follow these guidelines could result in an increased risk of loss of vehicle control, injury or death.

If you have a dissimilar spare wheel and tire, then it is intended for temporary use only. This means that if you need to use it, you should replace it as soon as possible with a road wheel and tire assembly that is the same size and type as the road tires and wheels that were originally provided by Ford. If the dissimilar spare tire or wheel is damaged, it should be replaced rather than repaired.

A dissimilar spare wheel and tire assembly is defined as a spare wheel and tire assembly that is different in brand, size, or appearance from the road tires and wheels and can be one of three types:

- T-type mini-spare: This spare tire begins with the letter T for tire size and may have Temporary Use Only molded in the sidewall.

- Full-size dissimilar spare with label on the wheel: This spare tire has a label on the wheel that states: THIS WHEEL AND TIRE ASSEMBLY FOR TEMPORARY USE ONLY.

When driving with one of the dissimilar spare tires listed above:- Do not exceed 50 mph (80 km/h).

- Do not load the vehicle beyond the maximum vehicle load rating listed on the Safety Compliance Label.

- Do not tow a trailer.

- Do not use snow chains on the end of the vehicle with the dissimilar spare tire.

- Do not use more than one dissimilar spare tire at a time.

- Do not use commercial car washing equipment.

- Do not try to repair the dissimilar spare tire.

- Using a dissimilar spare wheel and tire assembly can compromise the effectiveness of the following:

- Handling, stability and braking performance.

- Comfort and noise.

- Ground clearance and parking at curbs.

- Winter weather driving capability.

- Wet weather driving capability.

- All-wheel driving capability.

- Full-size dissimilar spare without a label on the wheel

When driving with the full-size dissimilar spare wheel and tire assembly:- Do not exceed 70 mph (113 km/h).

- Do not use more than one dissimilar spare wheel and tire assembly at a time.

- Do not use commercial car washing equipment.

- Do not use snow chains on the end of the vehicle with the dissimilar spare wheel and tire assembly.

- Using a dissimilar spare wheel and tire assembly can compromise the effectiveness of the following :

- Towing a trailer.

- Driving vehicles equipped with camper body.

- Driving vehicles with a load on the cargo rack.

Drive cautiously when using a full-size dissimilar spare wheel and tire assembly and seek service as soon as possible.

Tire Change Procedure

WARNING: The jack supplied with this vehicle is only intended for changing a flat tire in an emergency. Do not attempt to do any other work on your vehicle when it is supported by the jack, as your vehicle could slip off the jack. Failure to follow this instruction could result in personal injury or death.

WARNING: To help prevent your vehicle from moving when changing a wheel, shift the transmission into park (P), set the parking brake and use an appropriate block or wheel chock to secure the wheel diagonally opposite to the wheel being changed. For example, when changing the front left wheel, place an appropriate block or wheel chock on the right rear wheel.

WARNING: Do not attempt to change a tire on the side of the vehicle close to moving traffic. Pull far enough off the road to not obstruct the flow of traffic and avoid the danger of being hit when operating the jack or changing the wheel.

WARNING: Only use the jack provided as original equipment with your vehicle.

WARNING: The jack supplied with this vehicle is only intended for changing a flat tire in an emergency. Do not attempt to do any other work on your vehicle when it is supported by the jack, as your vehicle could slip off the jack. Failure to follow this instruction could result in personal injury or death.

WARNING: Only use the jack provided as original equipment with your vehicle.

WARNING: Never place anything between the vehicle jack and your vehicle.

WARNING: Never place anything between the vehicle jack and the ground.

WARNING: Only use the specified jacking points. If you use any other locations you could damage vehicle components, such as brake lines.

WARNING: Failure to follow these guidelines could result in an increased risk of loss of vehicle control, injury or death.

WARNING: Switch off the running boards before jacking or placing any object under your vehicle. Never place your hand between the extended running board and your vehicle. A moving running board may cause injury.

WARNING: Only use the spare wheel carrier to stow wheels provided with your vehicle.

Note: Passengers should not remain in your vehicle when the vehicle is being jacked.

Note: Do not use impact tools or power tools operating at over 200 RPM on the spare wheel carrier winch, which may cause it to malfunction and prevent a secure fit. Override the winch at least three times

(there is an audible click each time) to make sure the wheel and tire fit securely.

Note: No maintenance or additional lubrication of your jack is required over the service life of your vehicle.

- Park the vehicle on a level firm ground and activate the hazard flashers.

- Apply the parking brake, place the transmission in park (P), turn the engine off.

- 3. Block the wheel diagonally opposite the flat tire. For example, if the left front tire is flat, block the right rear wheel.

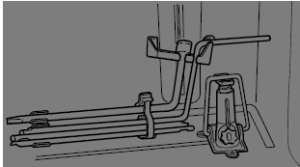

Removing the Jack and Tools

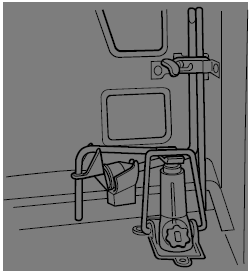

The jack and tools are located in the rear right-hand side of the cargo area. Remove the jack and tools from the storage location.

Jack and Tool Stowage Regular

Van/Wagon:

Jack and Tool Stowage Extended Van/Wagon:

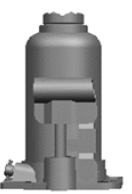

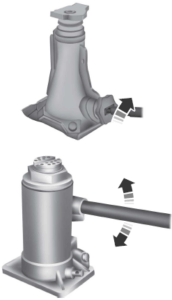

Hydraulic Jack:

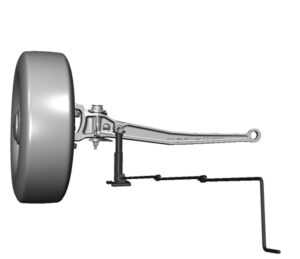

Removing the Spare Tire

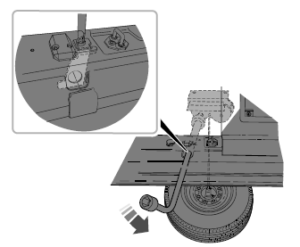

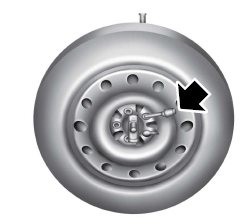

- To remove the spare tire, remove the jack handle from the right side compartment, open the rear doors and remove the thumb screw and anti-theft bracket. If finger pressure will not remove the thumb screw, use the lug nut wrench tip to loosen it.

- Remove the access cover from the rubber strip. Guide the lug wrench or jack handle through the hole and into the tube.

- Turn the wrench or handle counterclockwise until the cable has slack and the tire can be slid rearward.

- Remove the retainer from the spare tire and remove the spare tire.

- Use the lug nut wrench to remove the wheel trim, if equipped.

- Loosen each wheel lug nut one-half turn counterclockwise. Do not remove them until the wheel is raised off the ground.

- For E-350 dual wheel and E-450 equipped with hydraulic jacks, two handle extensions are used to operate the jack. To assemble, align the button with the hole and slide the parts together. To disconnect, press the button and pull apart.

Jacking the Vehicle

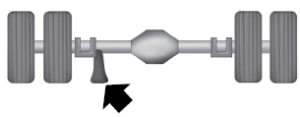

Position the jack under the correct jacking points according to following pictures.

Front axle jacking point: Place the jack under the pin on the front surface of the front axle.

Note: Do not place the jack under or on the steering linkage.

E201346

Rear axle jacking points: All models except E-350 and E-450 dual rear wheel.

Rear axle jacking points: E-350 and E-450 dual rear wheel.

Turn the jack handle clockwise. For hydraulic jacks, operate the handle

up-and-down until the wheel is completely off the ground and high enough to install the spare tire.

Installing the spare wheel and tire

- Remove the lug nuts with the lug wrench, replace the flat tire with the spare, making sure the valve stem of the spare is facing outward when replacing a front wheel. For the rear wheel position on vehicles with single rear wheel fitments, install the spare with the valve stem facing outward. For vehicles with dual rear wheels, the valve stem of the spare must face outward when replacing an inner wheel, but must face inward when replacing an outboard wheel.

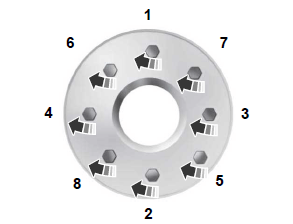

- 2. Install the lug nuts and finger tighten.

Do not fully tighten the lug nuts until the wheel has been lowered. - Lower the vehicle completely by turning the jack handle counterclockwise.

Note: For hydraulic jacks, insert the release valve, open release valve slightly by turning the handle counterclockwise. Stop turning the release valve when vehicle start to lower. Close the valve when the vehicle is completely lowered

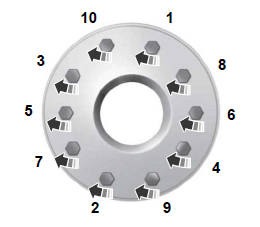

- Install the lug nuts in the sequence shown.

- Remove the jack and fully tighten the lug nuts in the sequence shown. See Technical Specifications (page 222).

- Install any wheel covers or hubcaps. Make sure they snap into place.

Note: When installing the wheel center ornaments, make sure that the ornament retention towers on the back side of the ornament are aligned with the studs and wheel nuts and retain to the flange on the wheel nuts.

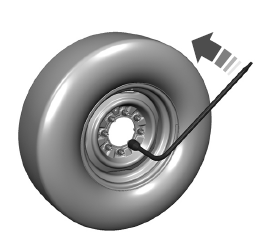

Stowing the Flat tire or Spare tire

- Place the tire on end with the valve stem facing toward the front of the vehicle. Lay the tire on the ground, near the rear of the vehicle, with the valve stem side facing up.

- Slide the wheel partially under the vehicle and install the retainer through the wheel center. If equipped, you may have to remove the wheel center cap prior to pushing the retainer through the center of the wheel. To remove the center cap, press it off with the lug wrench tip from the inner side of the wheel. Pull on the cable to align the components at the end of the cable.

- Turn the lug wrench clockwise until the tire is raised to its stowed position underneath the vehicle. The wrench becomes harder to turn and the spare tire winch ratchets or slips when the tire is raised to its maximum tightness. A clicking sound is heard from the winch indicating that the tire is properly stowed. Check that the tire lies flat against the frame and is properly tightened.

- Reinstall the tools and tighten the wing nut.

- Reinstall the jack properly into the bracket and tighten the wing nut.

- Unblock the wheel.

TECHNICAL SPECIFICATIONS

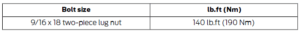

Wheel Lug Nut Torque Specifications

WARNING:

When you install a wheel, always remove any corrosion, dirt or foreign materials present on the mounting surfaces of the wheel or the surface of the wheel hub, brake drum or brake disc that contacts the wheel. Make sure to secure any fasteners that attach the rotor to the hub so they do not interfere with the mounting surfaces of the wheel. Installing wheels without correct metal-to-metal contact at the wheel mounting surfaces can cause the wheel nuts to loosen and the wheel to come off while your vehicle is in motion, resulting in loss of vehicle control, personal injury or death.

On vehicles equipped with single rear wheels, retighten the lug nuts to the specified torque at 100 miles (160 kilometers) after any wheel disturbance (such as tire rotation, changing a flat tire, wheel removal).

On vehicles equipped with dual rear wheels, retighten the wheel lug nuts to the specified torque at 100 miles (160 kilometers), and again at 500 miles (800 kilometers) of new vehicle operation and after any wheel disturbance (such as tire rotation, changing a flat tire, wheel removal).

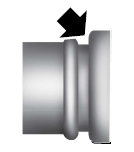

On all two-piece flat wheel nuts, apply one drop of motor oil between the flat washer and the nut. Do not apply motor oil to the wheel nut threads or the wheel stud threads.

Wheel pilot bore

Wheel pilot bore

Inspect the wheel pilot hole and mounting surface prior to installation.

Remove any visible corrosion or loose particles.

FAQs

Tire pressure recommendations can be found on the tire placard located inside the driver’s door jamb or in the owner’s manual.

While Ford usually offers a limited warranty on tires, the tire manufacturer might also provide a separate warranty.

Ford typically equips vehicles with reputable tire brands, but always consult the owner’s manual or dealership for specific recommendations.

Wheel size can vary depending on the trim level and optional packages. This information would be in the vehicle specifications.

Installing larger or aftermarket wheels can impact the vehicle’s handling and warranty. Always check with your dealership before making such modifications.

Regular tire rotation helps even out tire wear. Refer to the maintenance section in the owner’s manual for specific intervals.

Some models come with a full-size spare, while others might have a compact or “donut” spare. Check the vehicle’s storage or the manual for clarification.

While all-season tires may come standard, dedicated summer or winter tires might be advised depending on your region and driving conditions.

The TPMS usually triggers a warning light on the dashboard when tire pressure drops below a set level.

Changing rims can impact the TPMS. Ensure any new rims are compatible with the system and consult your dealership or a tire specialist before making changes.

Useful Links

View Full User Guide: FORD E-350 2023 User Guide

Download Manuals: https://www.ford.com/support/owner-manuals/owner-manuals-sitemap/

2023 FORD F-SERIES SUPER DUTY Specs, Price, Features and Mileage